Hendo Industry - Manufacturer of Spring Balancer, Air Tool Balancers, Push Pull Trolley and Air Balance Hoist

Spring Balancer

Hendo Industries is very famous name in the industry of Spring Balancer. We are one of the leading manufacturers of Spring Balancer in India located in Mumbai. Get different and wide range of Spring Balancer from us specially designed to free the operator from weight of the hand tools.. Our products are subject to high quality standards. So if you are looking for any kind of Spring Balancer then you are at right place on internet.

Spring Balancer:

A spring balance consists of a coiled spring fixed to a support at one end, with a hook at the other to which the body to be weighed is applied. Within the spring's limit of elasticity, the distance through which it is stretched is directly proportional to the weight of the applied body. A pointer and graduated scale attached to the spring convert this distance into a weight reading.

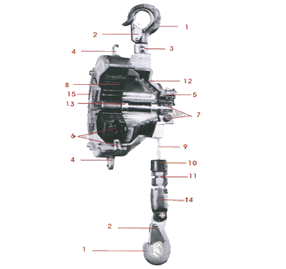

SECTIONAL VIEW OF HENDO SPRING BALANCER

• Forged Hooks - Ensure against breakage or bending.

• Forged Hooks - Ensure against breakage or bending.

• Safety Latch on Hooks - both top and bottom hooks have a safety latch to prevent accidental unhooking of either balancer or load.

• Swivel on Top Hook - allow full 360 degree rotation. Positions balancer for easiest cable flow, prolongs cable life.

• Hanger for Secondary Support Chain - Upper and Lower Hangers are provided for attachment of secondary support chain to prevent the possibility of the balancer accidentally falling.

• Manual Safety Lock - Positively locks rotation of the drum. A must when replacing a cable, changing the load or renewing the spring.

• Safety Stop Arm - Automatically locks the cable drum and holds the load in place if the main spring fails.

• Hardened Worm & Worm Gear Load Adjustment - Permits exact external balancing of load.

• Self-Contained Spring - Allow cable replacement without disassembly. Spring is retained in a steel collar.

• Stranded Steel Cable - Resists kinking ......reduces drum wear .......requires no lubrication .........outwears plain steel cable.

• Shock Absorber and (11) Adjustable Cable Stop - limits retraction of cable to any desired point in its travel. Prevents excessive winding of cable on drum

• Tapered Cable Drum - Assure more even tension in cable throughout working range.

• Steel Drum Shaft - Precision made for extra life and added safety.

• Hook Holder - Designed for easily exchange of Steel Cable Shock Absorbing Rubber and Forged Hook.

• Guage Indicator - Indicates set weight of the spring balancer.

ADVANTAGES OF USING HENDO MAKE SPRING BALANCERS

HENDO NEW HSB SERIES : HENDO make Spring balancers are specially designed to free the operator from carrying the weight of hand tools. The tools can be pulled down with least force, without any strain and fatigue. Handling of the tool becomes very easy as the load and pressure required for a particular operation is counter balanced in the mechanism of the Spring Balancer itself. The operation is free from gravitational force

RUGGED CONSTRUCTION : The main housing and cover are pressure die cast/gravity die cast from LM-6 grade aluminium for maximum resistance against impact & ease of handling. Upper support assembly is solid steel and in full contact with the steel support pins that attach it to the housing. Cables are stranded steel cable.

TAPERED CABLE DRUM : Unique cable drum design matches the middle turns of the spring , where the torque build-up is constant. This design feature provides smooth, even cable tension throughout entire length of cable travel.

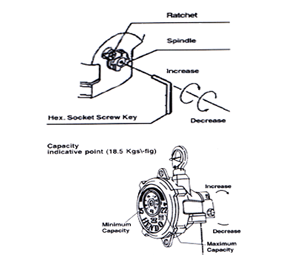

EXTERNAL TENSION ADJUSTMENT : External tension adjustment is easily accessible from the floor. Tension can be set at exact requirement through a hardened worm-gear system, no special tools needed.

SWIVEL ON THE TOP HOOK : Allow full 360° degree rotation. Positions balancer for easiest cable flow-prolongs cable life.

CONTAINERIZED MAIN SPRING : Model HSB -15 to HSB-200 comes with completely containerized (cartridge type) main spring . This eliminates the need for maintenance personnel to handle loose-dangerous springs.

AUTOMATIC DRUM LOCK : If spring tension declines sharply , an automatic locking mechanism immediately engages, preventing the load from falling.

MANUAL DRUM LOCK : Cables and Tools can be changed easily by engaging the manual drum lock. After tools or cable has been replaced - WITH FULL LOAD ATTACHED, manual drum lock can be released - DO NOT RELEASE MANUAL DRUM LOCK WITHOUT ATTACHING FULL LOAD. This can be done on the job site in a matter of minutes, without removing tension on the balancer cable. This convenience makes change over safe, simple and quick reducing costly downtime.

SELECTION OF THE BEST SUITABLE MODEL.

Select the correct model for the weight (Mass) of tools or instruments which will be hung. Weight means total weight , that is, tool plus cable hose plus other accesseries. (example)

Select the correct model for the weight (Mass) of tools or instruments which will be hung. Weight means total weight , that is, tool plus cable hose plus other accesseries. (example)

The weight of tools itself (14 kgs) + the weight of accesories (3 kgs) is equal to 17 Kgs (total weight). so, you should select HSB-22 MODEL (15~22Kgs.)

If the total weight in on the border of two models, you should select the LARGER model. This will benefit you since the balancer will have a longer life.

• Mount the balancers not to collide with structure.

• Keep the balancers uneven not to collide with each other.

• Attach the secondary support cable(or chain) to follow the moving of tools.

• Adjust the main spring tension to be appropriate to the weight (mass) of tool (or instrument).

• At Shipping , the main spring tension is set in the middle of its capacity. For increasing, turn the worm clockwise. For decreasing, turn the worm counterclockwise.

TOTAL LOAD - When selecting a balancer, first consideration should be given to the weight of the total load to be balanced (tool plus cable or hose plus other attachments). When the total weight has been determined , the balancer model with the proper tension (weight range) can be chosen. HENDO DELUXE series balancers have an external device for "on-the-job" tension adjustment. The adjustment range for each model is specified in the section tables.

BALANCER MOUNTING - For maximum operator efficiency and balancer life, the tool balancer should always be mounted directly over the work area, with the load perpendicular to the floor when in use. Working with the load not perpendicular causes operator fatigue and excessive wear on balancer cable and drum. when it is necessary to continually move the balancer and tool from one position to another, a system of trolleys and runways can be used.

CABLE TRAVEL - Cable travel is the total length of cable which can be installed in and pulled out of a balancer.

CABLE OVERHANG - Cable overhang is any additional length of cable attached to or part of the active cable, which is not retracted into the balancer. Overhang cable is often necessary for work area with high ceilings.

SECONDARY SUPPORT CHAIN - It is Strongly recommended that all balancers mounted overhead have a secondary support chain attached, to prevent the possibility of the balancer accidentally falling. The chain attaches in the balancer with the other end attached to a support other than the one that supports the balancer. The length of the chain should be kept to an absolute minimum.